Applications The versatility of the Octagonal Blender extends across diverse industries, including

- Pharmaceutical: Octagonal Blender Serving as a cornerstone in pharmaceutical manufacturing, the blender adeptly blends granules for the production of tablets, capsules, and powders.

- Food: In the culinary landscape, it plays a pivotal role in the mixing process for an array of food products, including spices, seasonings, and nutritional supplements.

- Chemical: Across chemical industries, it emerges as an indispensable tool for blending dry chemical compounds and formulations, spanning applications in fertilizers, detergents, and pigments.

- Cosmetic: In the realm of cosmetics, it facilitates the preparation of various formulations such as powders, creams, and lotions, ensuring consistency and quality.

Octagonal Blender Benefits for All Industries

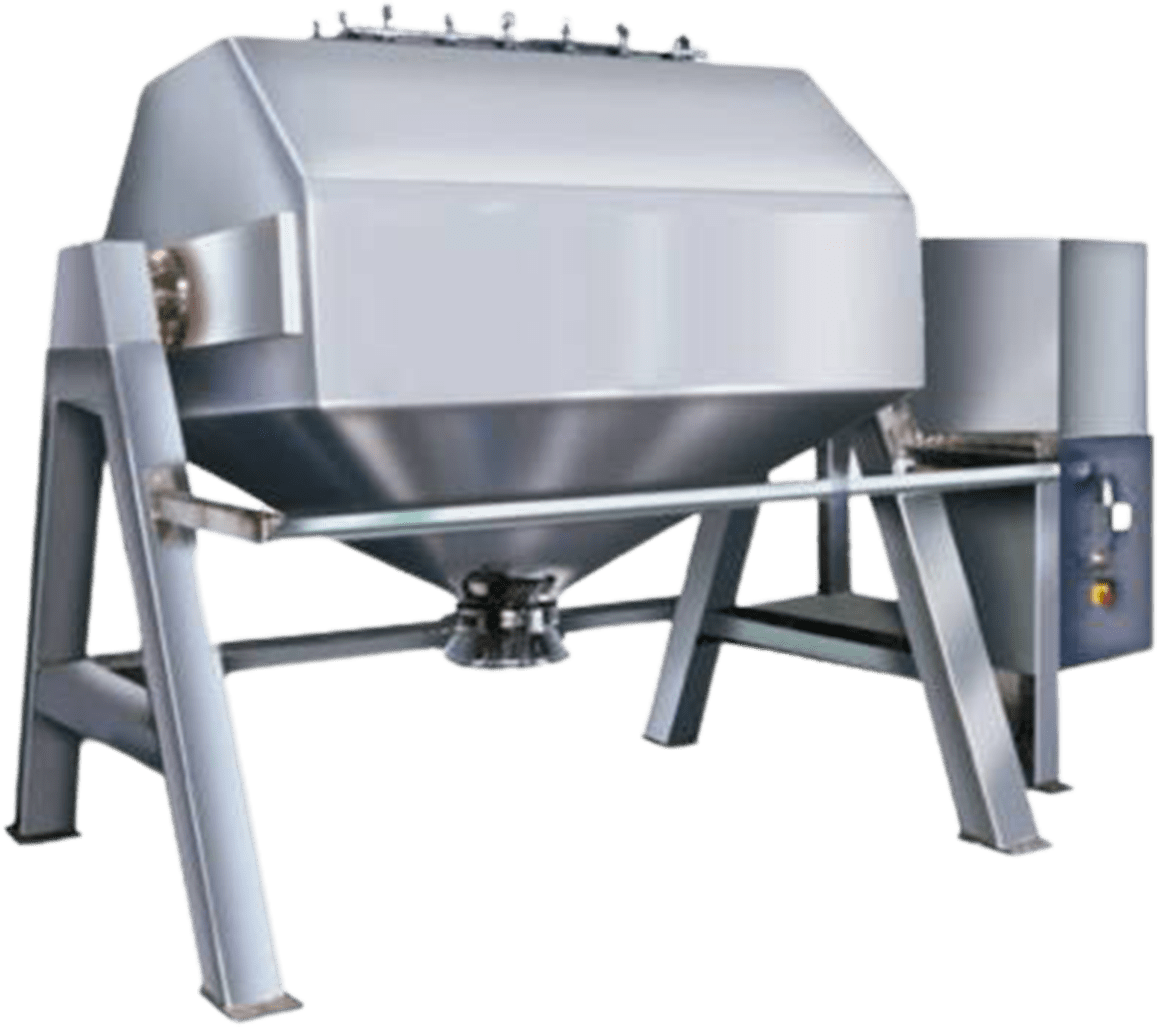

In the realm of blending machines, the Octagonal Blender emerges as a pinnacle of efficiency and adaptability. Specifically engineered to handle the mixing and lubrication processes of dry granules, this apparatus promises homogeneous blending with unparalleled precision. Let’s embark on a comprehensive journey to discover its remarkable features, wide-ranging applications, and significant impact across various industries.

Features:

- Efficient Mixing: The Octagonal Blender capitalizes on its unique octagonal shape and deliberate slow-speed operation to ensure comprehensive blending of dry granules. Typically, it optimizes blending efficiency by filling two-thirds of its volume.

- cGMP Compliance: Designed meticulously in accordance with stringent cGMP (Current Good Manufacturing Practices) standards, this blender guarantees products of the highest quality and safety, aligning with industry norms.

- Powerful Drive System: Enhanced with a robust reduction gearbox drive and a safety guard, the blender delivers consistent performance while prioritizing operator safety throughout operations.

- High-Quality Construction: Crafted with precision, all contact parts of the blender are fabricated from SS 316, ensuring durability, corrosion resistance, and adherence to stringent hygiene standards.

- Customization Options: The Octagonal Blender offers a wide array of optional features, ranging from bin loading to vacuum loading/unloading systems, tailored to meet specific production requirements and preferences.

By leveraging its varied capacities ranging from 150 liters to 3400 liters, along with precise motor capacities and discharge valve sizes, the Octagonal Blender caters to diverse production needs across different scales.

In conclusion, the Octagonal Blender stands as a reliable and indispensable asset in the manufacturing landscape, offering unmatched blending efficiency and versatility across a multitude of industries.

Technical Specification of Octagonal Blender

| Working Volume in Liters | Gross volume in Liters | Motor Capacity in H. P. | Discharge valve size in mm | Overall dimensions L X W X H in mm approx. |

|---|---|---|---|---|

| 300 | 375 | 1.5 | 150 | 2165 X 1535 X 2585 |

| 500 | 600 | 2 | 200 | 2250 X 1800 X 2700 |

| 600 | 725 | 2 | 200 | 2300 X 1800 X 2800 |

| 750 | 875 | 3 | 200 | 2300 X 1850 X 2800 |

| 800 | 950 | 3 | 200 | 2350 X 1000 X 2800 |

| 1000 | 1150 | 5 | 250 | 2700 X 2100 X 3050 |

| 1200 | 1300 | 5 | 250 | 2800 X 2270 X 3050 |

| 1500 | 1700 | 5 | 250 | 2850 X 2525 X 3120 |

| 2000 | 2200 | 7.5 | 300 | 2800 X 2800 X 3350 |

| 2500 | 2700 | 7.5 | 300 | 2800 X 2800 X 3450 |

| 2800 | 3500 | 10 | 300 | 2800 X 2900 X 3500 |

| 3400 | 4000 | 10 | 300 | 2900 X 3000 X 3700 |

Conclusion

The Octagonal Blender represents a reliable and indispensable asset in the manufacturing landscape, offering unparalleled blending efficiency and versatility across a multitude of industries. With its robust construction, precise operation, and adherence to industry standards, it continues to set the benchmark for blending excellence.

For further information on the Octagonal Blender and its applications, you may explore the following external resources:

- Chemical Engineering Portal – Blender Overview

- Pharmaceutical Processing Magazine – Mixing Technologies

- Food Manufacturing – Mixing Equipment Guide

By providing links to these external resources, readers can access additional insights and information on the Octagonal Blender and related topics. Should you need further elaboration on any aspect, feel free to ask!