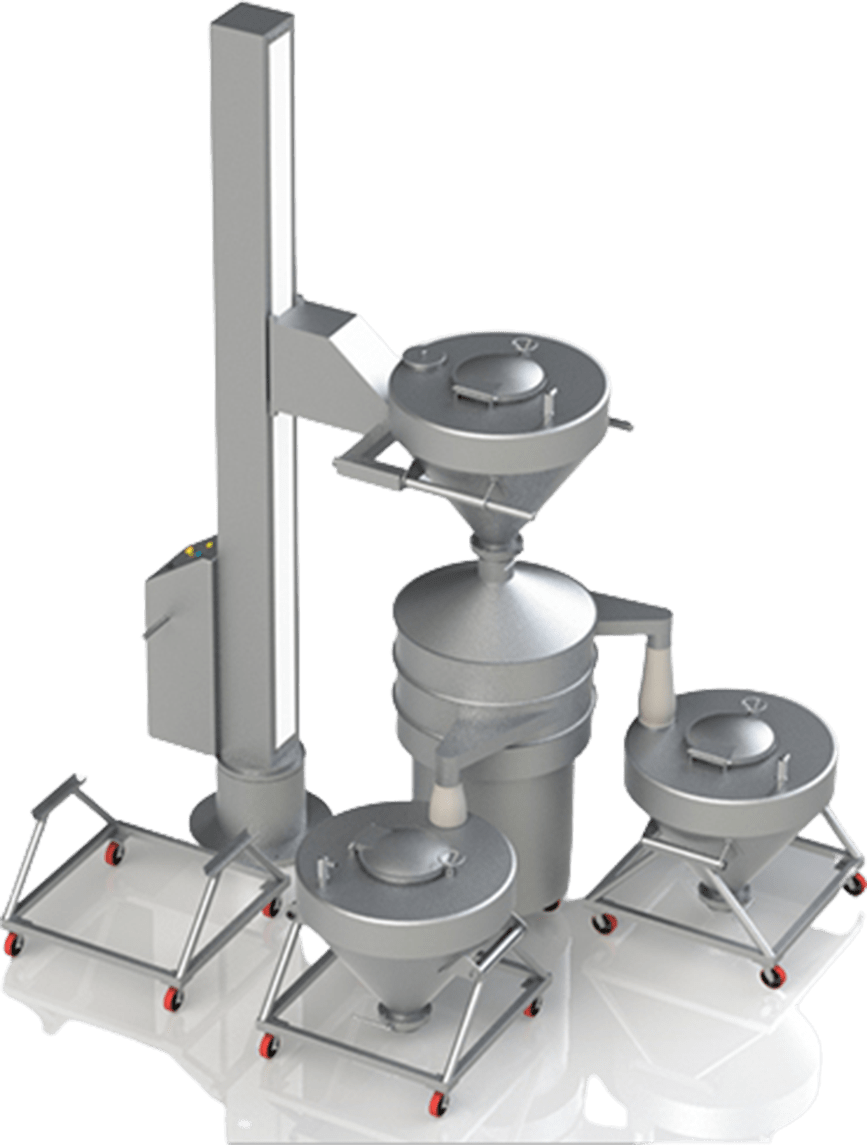

Key Aspects of Lifting and Positioning Device

- Lifting and Positioning Devices: Essential Tools for Enhancing Ergonomics and Safety in the Workplace

- Ergonomics and Safety: Lifting and positioning devices are engineered to mitigate the strain on workers, crucially minimizing the risk of injuries associated with lifting and manual handling tasks. These tools are fundamental in promoting a safer working environment, particularly in industries where physical loads pose a daily challenge.

- Precision: These devices are indispensable for enabling the precise positioning of objects, a necessity in applications demanding high accuracy levels, such as assembly lines or when handling sensitive materials. The precision afforded by lifting and positioning devices ensures efficiency and quality in operations, reducing the likelihood of errors.

- Versatility: The adaptability of many lifting and positioning devices is evidenced by their adjustable features, including height and angle adjustments. This versatility allows them to accommodate various tasks and interact with objects of differing sizes and shapes, making them invaluable across multiple sectors.

- Capacity: Lifting and positioning devices vary significantly in capacity, encompassing lightweight solutions for small components and extending to heavy-duty equipment capable of moving several tons. This range ensures that there are suitable options for operations of any scale, enhancing workflow and productivity.

Lifting And Positioning Device Capacity and Features:

- Capacity: The equipment boasts a maximum capacity of 1000 liters, making it suitable for a wide range of applications.

- Additional Features: Other notable features include robust construction, user-friendly controls, and compliance with industry standards for safety and hygiene.

Top Solutions for Lifting and Positioning Device Manufacturer

A Lifting and Positioning Device is engineered to enhance workplace efficiency, safety, and ergonomics by allowing operators to lift, move, and position loads with precision. These devices vary widely in design, capacity, and functionality to accommodate different industries and applications, from manufacturing and warehousing to construction and healthcare. Let’s explore the key aspects, types, and benefits of these devices.

Advantages:

- Improved Efficiency: By automating the Lifting and Positioning, systems can significantly improve efficiency by reducing manual labor and streamlining material transfer tasks.

- Enhanced Product Quality: Precise positioning ensures that materials are handled carefully and accurately, minimizing the risk of damage or contamination. This helps maintain product quality and consistency throughout the production process.

- Reduced Downtime: Reliable systems minimize downtime by providing consistent performance and minimizing the risk of equipment failure or malfunction. This leads to increased productivity and overall operational efficiency.

- Cost Savings: Automated systems reduce the need for manual labor, saving on labor costs and minimizing the risk of injuries or accidents. Additionally, efficient material handling can help reduce waste and optimize resource utilization, leading to cost savings in the long run.

- Versatility: Modern systems are highly versatile and can be customized to meet the specific needs of different industries and applications. Whether it’s lifting heavy machinery in manufacturing plants or transferring delicate materials in pharmaceutical facilities, these systems can adapt to a wide range of requirements.

Types of Lifting and Positioning Device

- Hoists: Electric, hydraulic, or pneumatic devices used to lift heavy loads vertically with a chain or wire rope.

- Lift Tables: Platforms designed to raise or lower goods and work materials to the appropriate heights for the operator.

- Jib Cranes: Stationary cranes that lift objects within a circular area, offering both vertical and horizontal movement.

- Manipulators: Mechanical devices that mimic human arm movement, ideal for picking, rotating, and precisely placing objects.

- Vacuum Lifters: Use suction cups and vacuum power to lift smooth-surfaced objects, such as glass or metal sheets.

- Pallet Lifters: Specifically designed to lift and transport pallets within warehouses and loading docks.

Technical Specification of Lifting and Positioning Device

| Model | Gross Capacity (ltrs.) | Working Capacity (ltrs.) | Working Capacity (kg.) |

|---|---|---|---|

| RMG-50 | 60 | 40 | 20 |

| RMG-100 | 125 | 80 | 40 |

| RMG-150 | 170 | 120 | 60 |

| RMG-250 | 280 | 200 | 100 |

| RMG-300 | 335 | 240 | 120 |

| RMG-400 | 450 | 320 | 160 |

| RMG-600 | 675 | 480 | 240 |

| RMG-700 | 785 | 560 | 280 |

| RMG-800 | 895 | 640 | 320 |

| RMG-1000 | 1120 | 800 | 400 |

| RMG-1200 | 1345 | 960 | 480 |

External Resources:

To delve deeper into the topic of lifting and positioning device equipment, consider exploring the following external resources:

- Material Handling & Storage Equipment Guide

- Fluid Bed Dryer Basics

- Hydraulic Systems and Equipment Overview

- Guide to Industrial Valve Types

These resources offer valuable insights and additional information to complement the content provided here.