Introduction to Double Cone Blender

Double cone blender, like the ones meticulously crafted by Bipin Pharma Equipment, play a pivotal role in blending and mixing dry powders and granules. These blenders are engineered to streamline manufacturing processes, enabling businesses to produce large quantities of products in remarkably short timeframes.

Advantages of Double Blender

Offer several advantages over alternative mixing methods:

- Gentle Mixing Action: The gentle tumbling motion of the double cone prevents degradation or damage to fragile ingredients, preserving product integrity.

- Efficient Homogenization: Ensures thorough blending of ingredients, eliminating segregation and achieving uniform distribution of particles throughout the mixture.

- Time and Cost Savings: Streamlines production processes, reducing mixing times and minimizing labor requirements, ultimately leading to cost savings.

- Versatility: Accommodates a wide range of batch sizes and material types, providing flexibility to adapt to varying production needs.

- Compliance and Quality Assurance: Designed in compliance with industry standards and regulations, ensuring product safety, purity, and consistency.

Elevate Efficiency: Double Cone Blender for Mixing

Features and Specifications

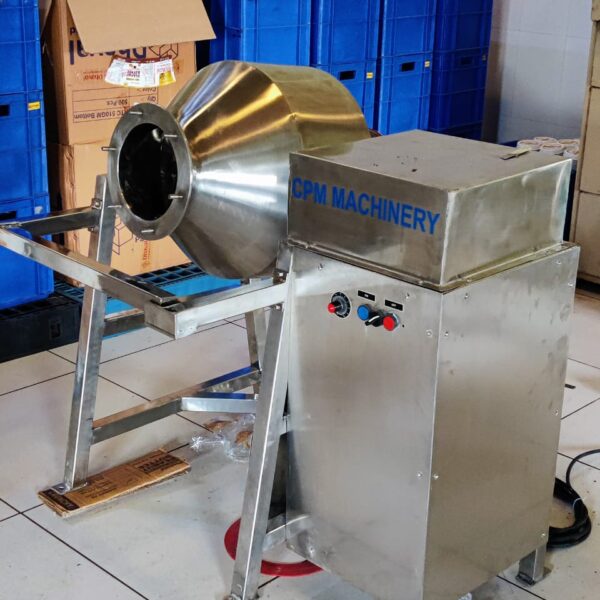

Concept Pharmatech PMM Double Cone Blending Machine boasts an array of features designed to optimize performance and ease of use:

- Material Variants: Available in GMP (Good Manufacturing Practice), standard, and laboratory models, ensuring compatibility with diverse industry requirements.

- High-Quality Construction: Crafted from durable materials such as stainless steel (SS 316L, SS 316, or SS 304), ensuring longevity and resistance to corrosion.

- Safety Measures: Equipped with safety guards to prevent accidents and ensure operator well-being during operation.

- Ease of Maintenance: Designed for convenient maintenance and cleaning, reducing downtime and enhancing operational efficiency.

- Optional Vacuum Charging System: Enhances flexibility and efficiency in material loading, particularly for sensitive or delicate ingredients.

- Range of Capacities: Available in a wide range of capacities, from 100 to 6000 liters, catering to the needs of both small-scale and large-scale production facilities.

Applications Across Industries

The versatility of double cone blender makes them indispensable across various industries:

- Pharmaceuticals: Ideal for blending active pharmaceutical ingredients (APIs), excipients, and other powdered substances to ensure uniform distribution and potency.

- Food and Beverage: Used in the production of dry mixes, nutritional supplements, flavorings, and food additives, maintaining consistency and quality in the final products.

- Chemicals: Facilitate the blending of powdered chemicals, catalysts, and pigments, crucial for the manufacturing of paints, dyes, fertilizers, and more.

- Cosmetics: Essential for homogenizing powders used in cosmetics and personal care products, ensuring a smooth and uniform texture.

Technical Specification of Double Cone Blender

| MODEL | GROSS CAP. LITER | NWORKING CAP. | RPM | HP |

|---|---|---|---|---|

| BPE-1 | 30 | 20 | 20 | 0.5 |

| BPE-2 | 150 | 100 | 20 | 1.5 |

| BPE-3 | 300 | 200 | 20 | 2 |

| BPE-4 | 500 | 350 | 20 | 2 |

| BPE-5 | 1000 | 750 | 20 | 3 |

| BPE-6 | 1500 | 1000 | 20 | 5 |

| BPE-7 | 2000 | 1400 | 20 | 7.5 |

| BPE-8 | 2500 | 1750 | 20 | 10 |

Conclusion

In conclusion, double cone represent a cornerstone of modern industrial mixing, offering unparalleled efficiency, versatility, and quality assurance. Bipin Pharma Equipment’s commitment to innovation and excellence ensures that their double cone stand at the forefront of manufacturing technology, empowering businesses across diverse sectors to meet the evolving demands of consumers with confidence and precision.

For further exploration of double cone and their applications in industrial mixing, you may find the following external resources helpful:

- Overview of Double Cone Technology

- International Journal of Pharmaceutics – Advances in Pharmaceutical Mixing Techniques

- Food Processing Magazine – Guide to Industrial Mixing Equipment

By delving into these external resources, readers can gain deeper insights into double blender and related topics, enhancing their understanding of this transformative technology. If you require further elaboration on any aspect, please feel free to ask!