About Us

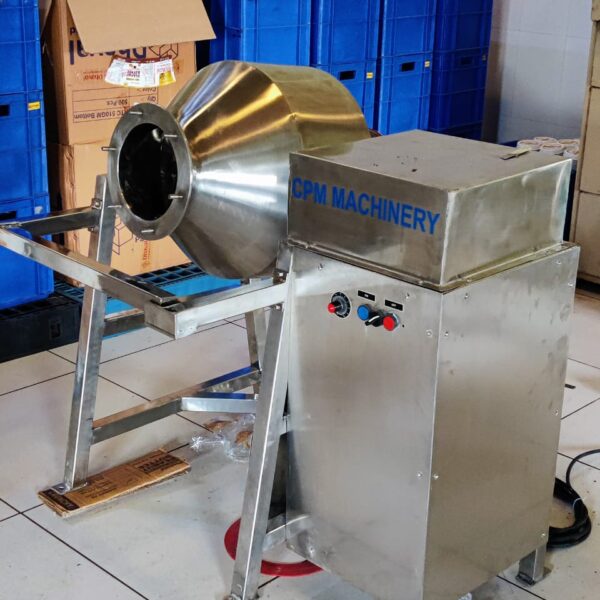

Concept PharmaTech Machinery specializes in manufacturing standardized machinery for the pharmaceutical industry, including auto-coaters, conta blenders, octagonal blenders, double cone blenders, and coating pans. With a deep understanding of pharmaceutical machine manufacturing, we have continuously adapted to the evolving needs of the industry. Our uniqueness lies in our ability to address technical queries and prioritize customer satisfaction. We attribute our growth to the valuable suggestions of our customers, and we are committed to expanding our presence pan-India and globally.

Why Concept Pharmatech

- Advance Technology

- Superior Quality

- Competitive Prices

- Assured Performance

Industries We Serve

Latest News & Blog

Concept PharmaTech: Elevating Machinery Excellence through Determination, Honesty, and Hard Work

At Concept Pharmatech Machinery, we’re more than just manufacturers – we’re partners in progress. With a steadfast commitment to excellence, we lead the machinery industry with our unwavering focus on determination, honesty, and hard work.

Determination: Driven by a passion for innovation, we continuously push the boundaries of possibility. Our relentless pursuit of improvement ensures that we stay ahead of the curve, delivering cutting-edge solutions that meet the ever-evolving needs of the pharmaceutical industry.

Honesty: Transparency and integrity are the cornerstones of our operations. We believe in doing business with honesty and integrity, earning the trust of our customers through open communication and ethical practices. With Concept Pharmatech, you can always count on straightforward dealings and reliable service.

Hard Work: Behind every piece of machinery we produce is a team of dedicated professionals working tirelessly to deliver excellence. From our skilled engineers and technicians to our customer support staff, every member of the Concept Pharmatech team is committed to delivering high-quality products and unparalleled service. It’s this dedication to hard work that drives us forward, propelling the pharmaceutical industry towards new heights of success.

Get in Touch

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Bauer Internation

112 W 34th St, New York

Find Us on Map

Mobile

9173207347

Our Email

sales@cpmmachinery.in

conceptpharmatech13@gmail.com

Let's Talk About Your Project

After we get some information from you, we’ll set up a time to discuss your project in further detail.